Home »

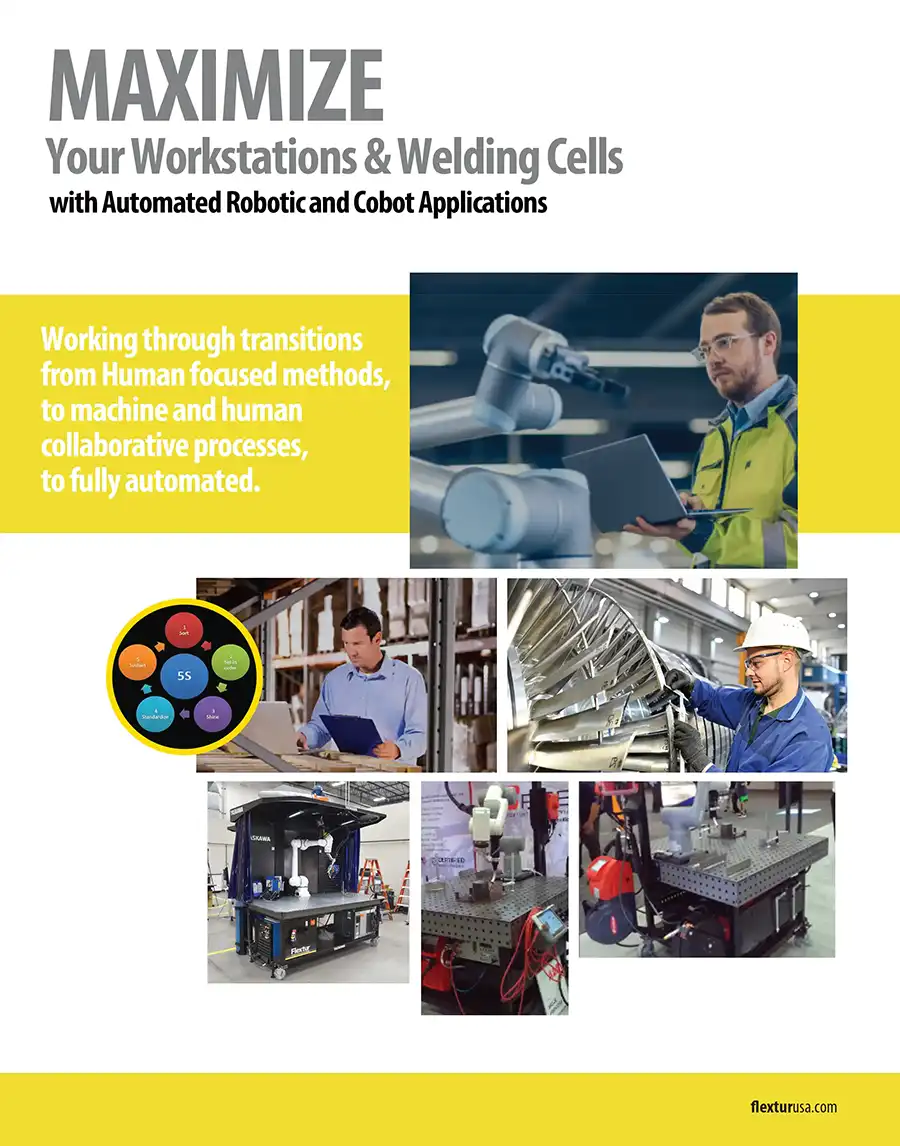

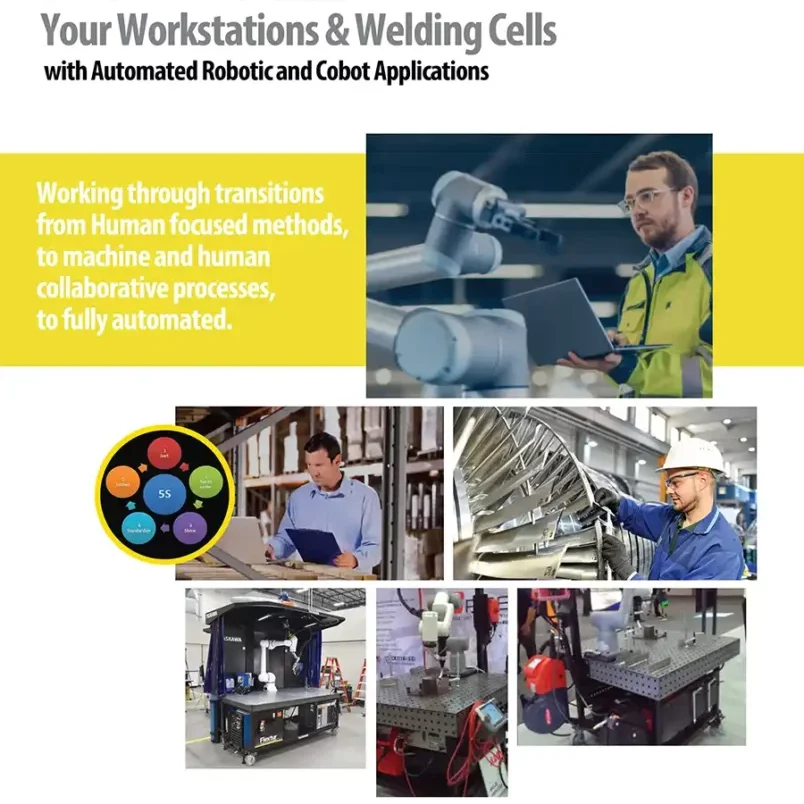

Do you operate a fully automated facility and want to maximize your Robotic/Cobot workstation to achieve greater efficiency? Or maybe you're new to automation and need to integrate cobots into your facility and manufacturing workflow to create efficient machine-to-human collaborative processes.

Robotics/Cobots offer a much-needed solution to the current labor shortage. The lack of skilled workers to achieve manufacturing production goals is a serious problem for many businesses. Robotics/Cobots solve by performing tasks with greater strength, accuracy, and data capabilities. But to keep up with production, organizations must utilize Lean methodologies to create these greater efficiencies.

In this eBook, you will…

- Learn ways to create a Lean and ergonomic workstation by utilizing Lean methodology to ensure maximum throughput and safety where humans & Robotics/Cobots collaborate.

- Learn the 7-Steps to integrate Lean workstations into robotic/cobot applications.

- Understand the top safety concerns with Industrial Robotics/Cobot workstation hazards and how to avoid them.

Get Your Free eBook Today!

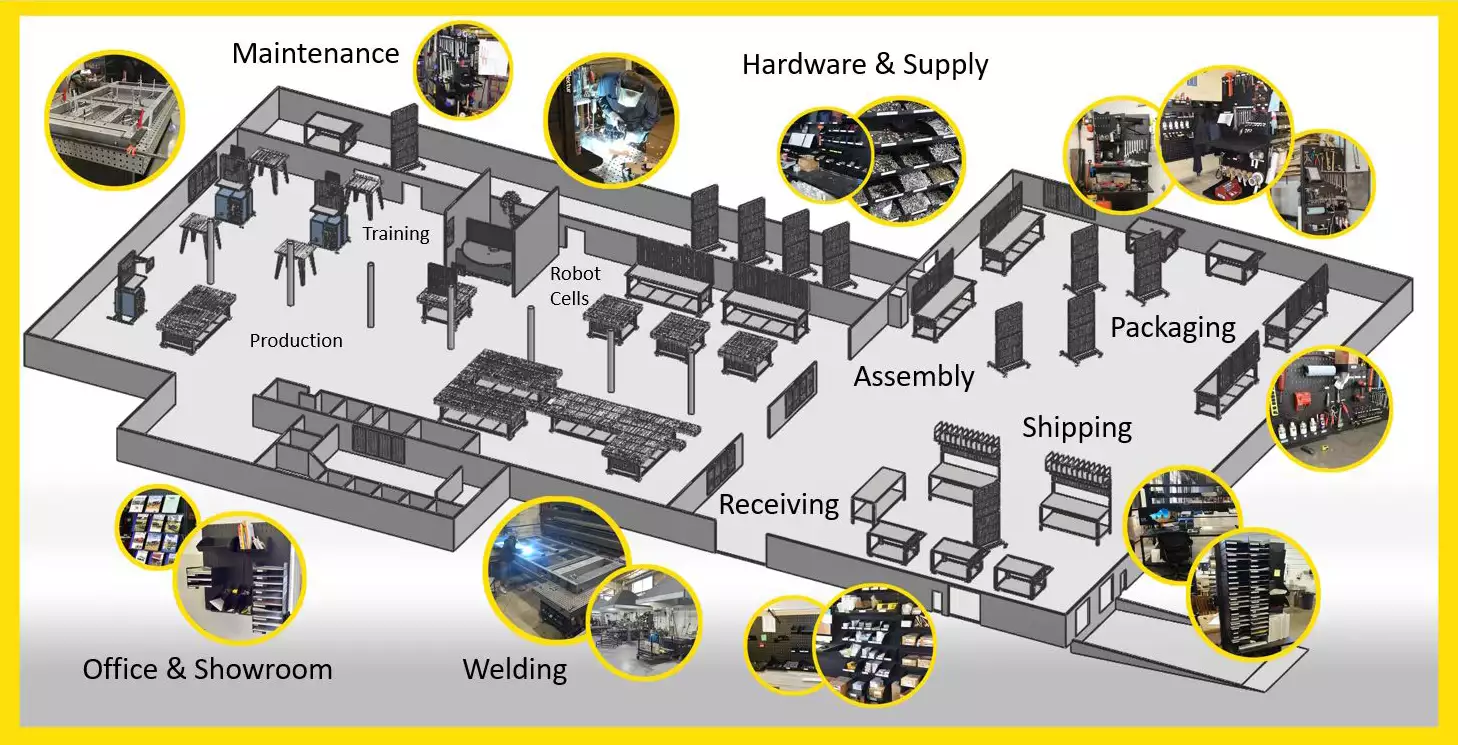

Organize & Standardize Your Facility

Outfit your facility for maximum productivity

By organizing and standardizing your facility using Flextur workstations, tool boards, and accessories, you will decrease labor and material costs, improve product quality, and organize your tool and material storage. Enhance 5S, Lean, and OSHA compliance efforts providing a safer working environment for your employees and visitors.